Conveyors and System Integration

- EVCO Engineered Solutions designs custom engineered solutions for your conveyance and integration needs.

- Below are some different types of high ROI conveyor and system intrations we design.

- Don’t see a solution for your product? Contact us and let us know what you need!

- Don’t know what you need? Contact us for a free consultation!

Why is system integration necessary for a quality finish? Check out our knowledge page to read more about the importance systems integration.

System Integration and Design

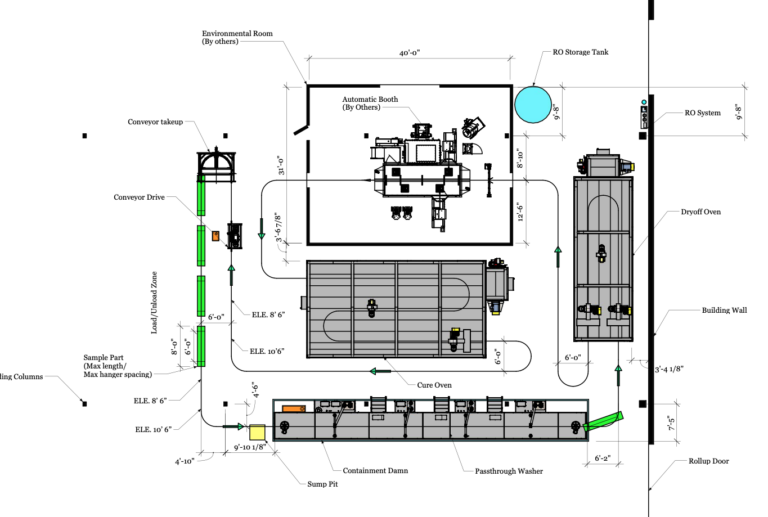

- Equipment Layout

Equipment layout is critical to the success of a system. Dryoff Ovens needs to be close to a washer as to prevent flash rust but and not too close to the powder booth for example. EVCO’s engineers balances the distance between each piece of equipment to make a compact system in the available space.

- Equipment Control Systems:

The controls for each piece of equipment is designed to be simple to use, non-proprietary and independant from all other equipment for robust reliability and easy servicability.

- Part Hanging System:

Based on your needs, we design inexpensive Load bars, use individualized hooks, saw tooth style mini-load bars or any other similar systems to allow for a simple part hanig solution.

- Simple Design, Great Results:

Our philosophy for system integration is to keep everything as simple as possible. It is tempting to add proprietary software, specialized sensors or fancy logic controllers. Our simple systems are easy to setup, easy to maintain and simple to operate using many off the shelf components and hard automation as possible.

Enclosed Track Conveyors

- Reduced Maintenance:

The enclosed design shields the conveyor components from dust, dirt, and other contaminants, minimizing wear and tear and reducing the need for frequent cleaning and repair.

- Minimizes Contamination:

Enclosed conveyors prevent contaminants from entering the system, protecting both the conveyed materials and the conveyor components.

- Space Efficiency:

Their design allows for tighter turn radii, changes in elevation, and even inverted configurations, maximizing space utilization.

- Adaptability:

Enclosed track conveyors are versatile and can be adapted to a variety of applications, including paint and finishing lines, assembly processes, and even home workshops.

- Reduced Downtime:By protecting the conveyor components, enclosed track systems minimize the risk of breakdowns and reduce the time spent on maintenance, leading to increased productivity.

I-beam conveyors

- Space Efficiency: I-beam conveyors are installed overhead, freeing up valuable floor space for other operations.

- High Load Capacity: Their sturdy steel construction allows them to handle heavy loads.

- Versatility: They can be adapted to various products and environments, including those with heat or corrosive conditions.

- Durability and Reliability: I-beam conveyors are known for their rugged construction, requiring minimal maintenance. .